3D Printers 101

3D printing may seem hard, but this should introduce you to all the basic concepts and ideas in 3D printing.

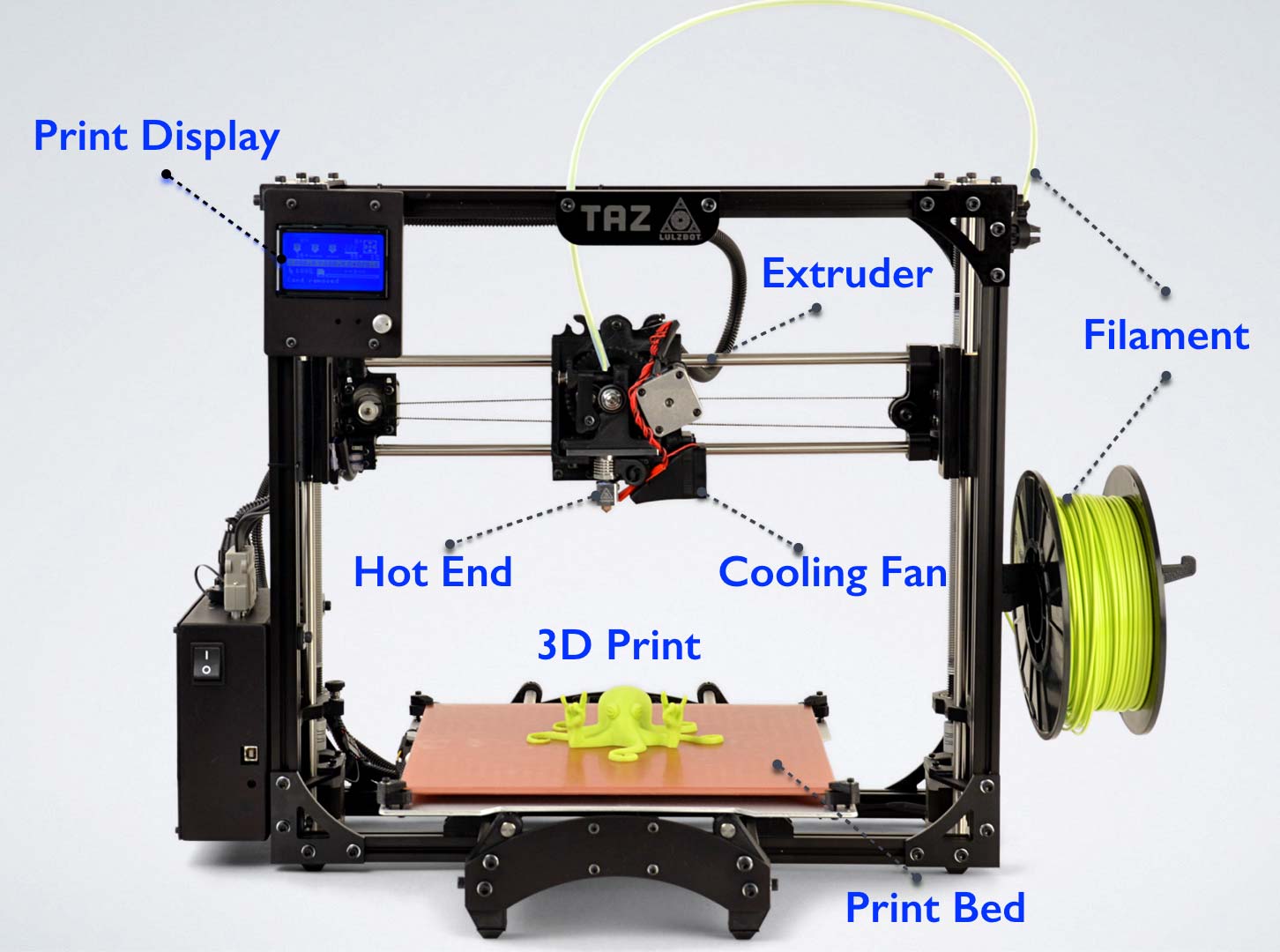

Parts of a 3D Printer

Just the important parts and their names. We will be calling them by these names as we go on.

Source: http://my3dconcepts.com/explore/main-components-of-desktop-3d-printers/

Source: http://my3dconcepts.com/explore/main-components-of-desktop-3d-printers/

Note: not all printers look like this, but this is a good starting point.

Types of Printers

In 3D printing, we have generally two types of printers. FDM (Fused Deposition Modeling) printers and SLA (Stereolithography Apparatus) printers. Yeah I know, big words you say, lets explain them in simpler terms.

FDM (Fused Deposition Modeling) Printers

So what are they. In FDM, a strand of material (filament) is deposited in layers to create a 3D printed object. During printing, the plastic filament is fed through the extruder where the plastic mets and is then deposited layer by layer in the print area to build the workpiece. By building layer by layer, a 3D object is thus printed.

Typically, there are many forms of FDM printers, but the most common ones are the Cartesian Printers and Delta Printers. Big words, heres a picture to help you.

Cartesian Printer

Essentially, Catesian printers have a movable bed, and x,y,z axis motors. The extruder sits on the X-axis and Y-axis, where it can move in four directions on a gantry. There are variations but this is the most common.

Delta Printer

Delta printers have a circular print bed and the extruder is suspended above the print bed by three arms in a triangular configuration, thus the name “Delta”. Delta 3D printers were designed for speed, but they also have the distinction of a print bed that never moves.

There are many other variations but this are the common types.

SLA (Stereolithography Apparatus) printers

In SLA, models are also built layer by layer. However, instead of using plastic filament, UV sensitive resin is used insead. The resin is hardened by applying focused light or UV light (this process is called curing). SLA printers usually build the models from top to bottom, the build platform lifts the model upwards, out of the resin tank.

However, because SLA printers make use of resin, the process of processing prints becomes more complex. After printing, one would have to wash the print by soaking it in Isopropyl alcohol (IPA). After which prints must dry and be cured before being safe to handle.

So what printer?

Generally, FDM printers are more budget friendly :) and also precise enough for daily usage. FDM printers are fast, really fast and are great for most prints. FDM printers can also print high strength filaments that have differenct physical propeties. However, if you are looking for ultra precision and dont mind long print times and curing times, you may want to consider SLA printers. Resin prints are also not as strong or durable as FDM prints.

Recently however, SLA printers have also started becoming budget friendly. In general, FDM prints are fast and strong while Resin prints are slow but with high precision and surface finish.

Some side notes

So in our school (ACSI) we have multiple 3D printers. All of our 3D printers are Cartessian printers which allows fast and relatively acurrate prints.